MIL-PRF-85036B(AS)

4.5 Sealing instructions for conformance and first article testing.

a. All seals for test purposes shall be not less than 1/2-inch wide and shall be effected on a

jaw-type heat-sealer or equivalent utilizing the sealing conditions recommended by the

manufacturer. A temperature setting of 525 °F, a 3-second dwell time, and a pressure of

60 pounds per square inch shall be used for all test seals (see 6.3).

b. In securing the three 1-inch seam strength specimens from their respective samples

(see 4.6.2.2.1), specimens shall not be removed:

(1) From points in the sealed sample where seal overlapping has occurred.

(2) From points in the sealed sample that were within 1-inch of either end

of the sealer jaw during the sealing operation.

4.6 Verification of performance requirements.

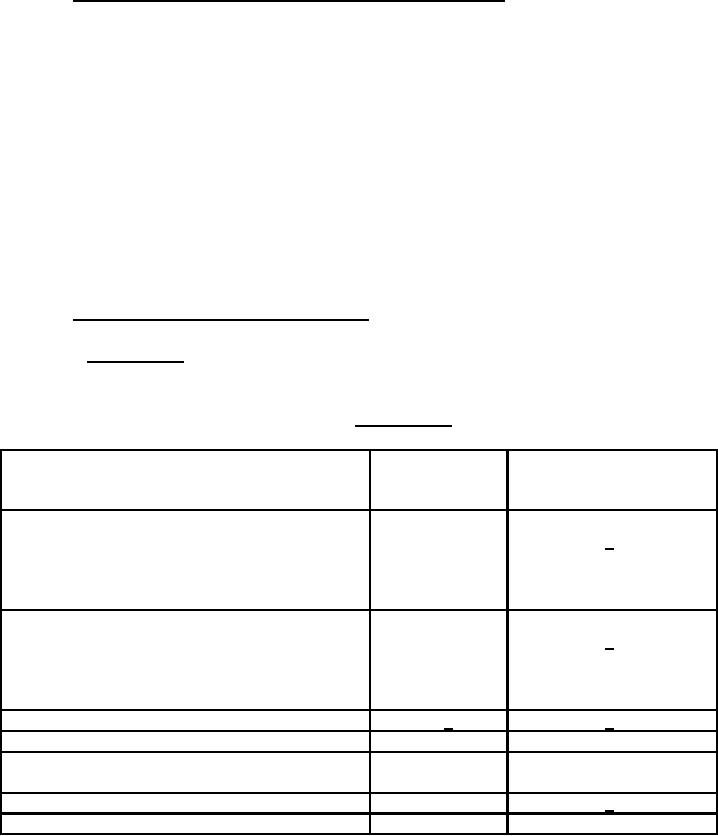

4.6.1 Test methods. Unless otherwise specified, the tests in table III shall be in accordance

with the identified methods of FED-STD-101.

TABLE III. Test methods.

FED-STD-101

SPECIAL REQUIREMENT

TESTS

TEST

OR EXCEPTION

METHOD NO.

NOTE

Water vapor transmission rate (WVTR)

After room temperature flexing (as received and aged)

2017

1/

Transmission rate procedure

3030

--

procedure A(1)

Water vapor transmission rate (WVTR)

After low temperature flexing (as received only)

2017

2/

Transmission rate procedure

3030

--

procedure A(1)

Breaking strength (grab method)

see 3/

3/

Puncture resistance

2065

Blocking resistance

3003

procedure D

Resistance to curl

2015

4/

Contact corrosivity

3005

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business