MIL-PRF-85036B(AS)

4.2 First article inspection. First article inspection shall include all examinations and tests of

this specification.

4.3 Conformance inspection. Conformance inspections shall consist of the required

examinations specified in 4.3.2.1 and the tests listed in table II.

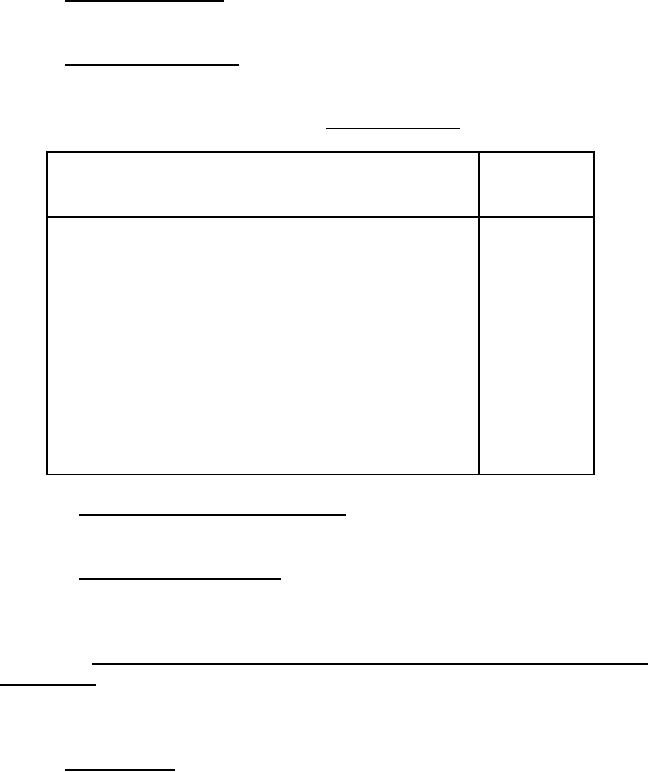

TABLE II. Conformance tests.

Characteristics

Paragraph

Reference

Seam strength at room temperature (face to face seam)

--

As received

4.6.2.2

Sealed then aged 12 days at 160° F

4.6.2.4

--

Seam strength at room temperature (face to back seam)

4.6.3.2

As received

Sealed then aged 12 days at 160° F

4.6.3.4

4.6.4

Seam fabrication (fin seal)

--

Water vapor transmission rate

As received; flexed in each direction

4.6.1

Puncture resistance

4.6.1

Resistance to curl

4.6.1

Oil resistance (delamination)

4.6.6

4.3.1 Sampling for conformance inspection. Unless otherwise specified, sampling for

inspection shall be performed in accordance with the provisions specified in ASQC-Z1.4.

4.3.2 Examination of the end item. For the purpose of determining the sample size in

accordance with ASQC-Z1.4, the lot size shall be expressed in units of rolls or packages of

sheets, as applicable, for examinations specified in 4.3.2.1.

4.3.2.1 Examination of the end item for construction, form, identification, sealing and

workmanship. The sample unit for the end item inspection shall be one roll or package of sheets.

The sample unit shall be visually inspected and measured to ensure it meets the requirements

specified in 3.3 through 3.7.

4.4 Test conditions. Unless otherwise specified in the test methods herein, the physical tests

contained in this specification shall be made with an atmosphere having a relative humidity of

50 ± 5 percent and at room temperature which shall have a range from 70 to 76 °F. Material shall

be considered in equilibrium after exposure to the above conditions for a minimum of 24 hours.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business