MIL-PRF-85036B(AS)

3.7 Workmanship. Barrier material surfaces shall be free from any foreign matter. The

barrier material edges shall be cut and trimmed of any selvage. Barrier material shall be free from

holes, tears, cuts, sharp creases, wrinkles, or other imperfections (see 4.3.2.1).

3.8 Performance requirements. The performance of the barrier materials shall meet the

requirements specified in table I, when tested in accordance with 4.6.

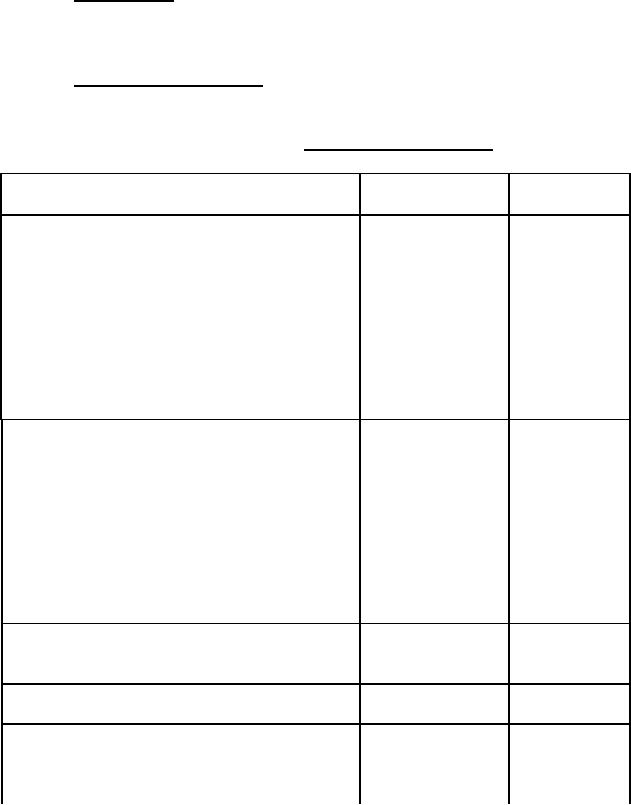

TABLE I. Performance requirements.

TEST

CHARACTERISTICS

REQUIREMENTS

PARAGRAPH

Seam strength (face to face seal)

4.6.2

1. Sealed as received:

a. At room temperature (separationinches)

No separation

b. At 100 °F and 160 °F (separation-inches)

1/4 max

2. Sealed, then aged 12 days at 160 °F:

No separation

a. At room temperature (separation-inches)

b. At 100 °F and 160 °F (separation-inches)

1/4 max

3. Aged 12 days at 160 °F, then sealed:

No separation

a. At room temperature (separation-inches)

b. At 100 °F and 160 °F (separation-inches)

1/4 max

Seam strength (face to back seal)

4.6.3

1. Sealed as received:

a. At room temperature (separation-inches)

No separation

b. At 100 °F and 160 °F (separation-inches)

1/4 max

2. Sealed, then aged 12 days at 160 °F:

No separation

a. At room temperature (separation-inches)

b. At 100 °F and 160 °F (separation-inches)

1/4 max

3. Aged 12 days at 160 °F, then sealed:

No separation

a. At room temperature (separation-inches)

b. At 100 °F and 160 °F (separation-inches)

1/4 max

Seam fabrication (face to face seal)

No leakage at

4.6.4

double seam

junction

Aging resistance

No delamination

4.6.5

Oil resistance (delamination)

No leakage,

4.6.6

swelling,

delamination, or

embrittlement

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business