MIL-PRF-22191F

3.5 Sealing. Barrier materials shall be heat-sealed under conditions recommended by the

manufacturer. These sealing conditions shall be conditions that are considered reasonable for

production line sealing operations with respect to commonly available sealing equipment and

commercially practical fabrication time. The material shall exhibit no delamination at the heat-

sealed area when sealed under the manufacturer's recommended conditions (see 4.5). Each roll

or package (flat cuts) of barrier material shall include a tag secured to the core of rolls, or sheet

inserted in the package of sheets with the sealing instructions for heat-sealing on rotary, band,

and jaw-type sealing equipment. The tag or sheet shall be visible upon opening the unit package

(see 4.3.2.2).

3.6 Identification of material. The specification number, type, class, manufacturer's name,

manufacturer's designation, month and year of manufacture, lot number, heat sealing conditions

(temperature, pressure and dwell time) and the notation "Seal other Side" if applicable shall be

clearly and legibly marked using water-resistant ink on the non-sealable side of the barrier

material. The color of the markings shall be blue. The complete markings shall be continuous

lengthwise and the distance between groups of markings shall be not greater than 2 inches. A

complete group of markings shall appear once in each 2-1/2 inches of width of the roll. The

letters and figures shall be not less than 1/8 of an inch high (see 4.3.2.3).

3.7 Performance requirements. The performance of the barrier materials shall conform to

the requirements specified in table I, when tested in accordance with 4.6.

3.8 Workmanship. Barrier material surfaces shall be free from any foreign matter. The

barrier material edges shall be cut and trimmed of any selvage. Barrier material shall be free

from holes, tears, cuts, sharp creases, wrinkles, or other imperfections (see 4.3.2.1).

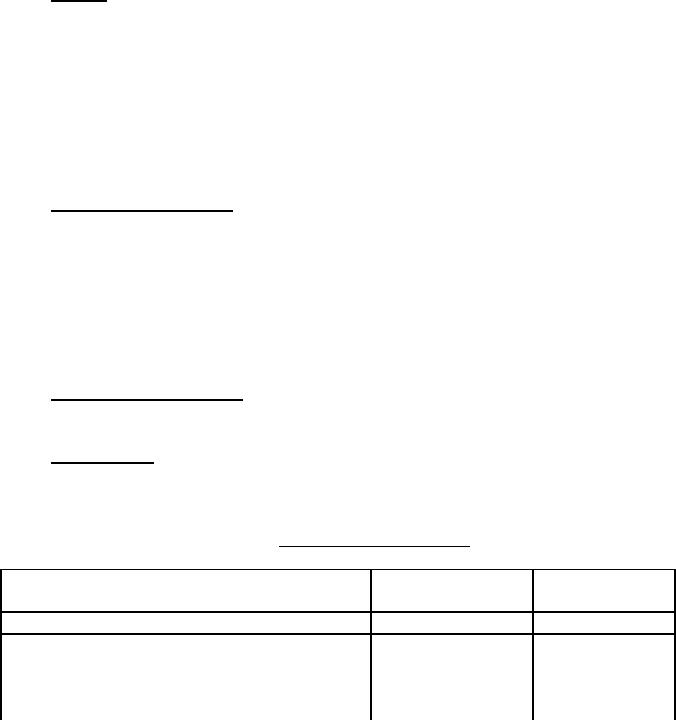

TABLE I. Performance requirements.

Types I, II, III

Test Paragraph

Characteristics

Requirements

Reference

Thickness (inches)(max)

0.0060

4.6.1

Seam Strength

4.6.1

1. As received material sealed & tested:

a. At room temperature (separation-inches)

No separation

b. At 100 °F and at 160 °F (separation-inches)

No separation

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business