MIL-PRF-22191F

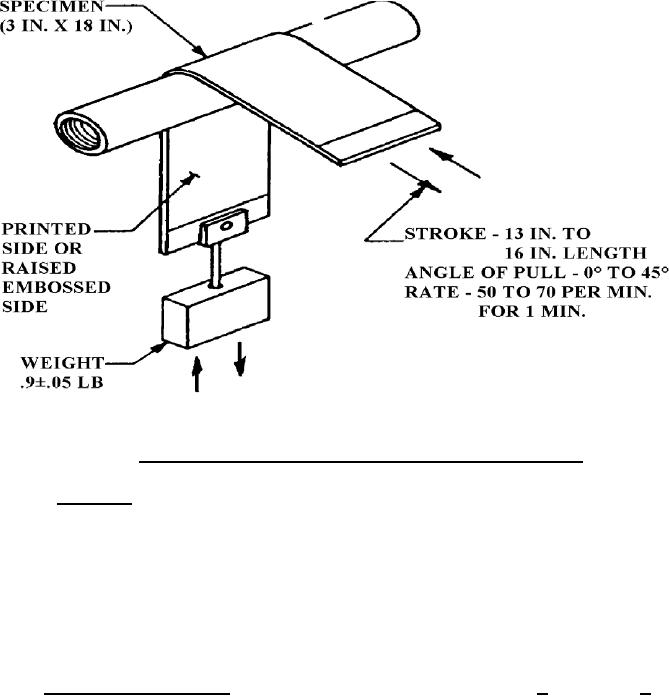

seam is formed and stapled, the resultant strip shall be 3 inches wide by 18 inches long as shown

on figure 2.

FIGURE 2. Apparatus for testing identity markings resistance to abrasion.

4.6.5.2 Procedure. The test bar shall be a 1-1/2 inch diameter cylinder with 400 grit

abrasive cloth secured (grit side out) to the entire surface area with double faced pressure

sensitive tape. The strip shall be hung over the bar with 0.9 ± 0.5 pound weight attached to one

end as shown on figure 2. The side with the print or raised embossing shall be in contact with

the bar. The other end shall be pulled (stroked) at a rate of 50 to 70 strokes per minute for 1

minute. The stroke length shall be 13 to 16 inches. The angle of pull (stroke) shall be from 0 to

45 degrees. The strip shall be removed and the weight detached. The printing shall be examined

for legibility, smear, and blurring.

4.6.6 One year storage stability. After one year of sheltered storage at 75 + 2 °F and 50 + 5

percent relative humidity, a sample of material (or sheets, if applicable) shall be tested for

conformance to the requirements of the following tests:

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business