MIL-PRF-22191F

4.6.2 Seam fabrication.

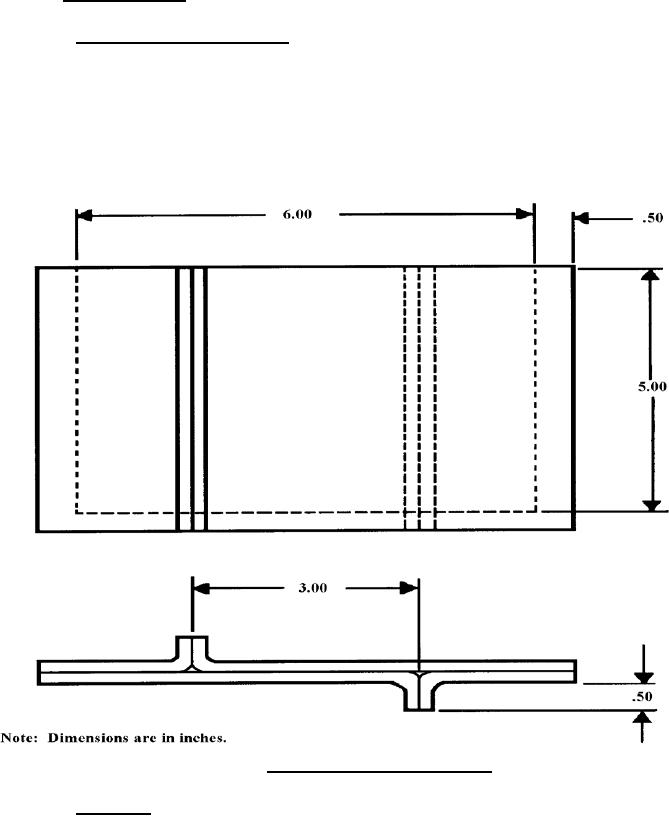

4.6.2.1 Preparation of test specimens. Four pouches sealed in accordance with the

manufacturer's recommended sealing conditions shall be fabricated from the barrier material.

Each pouch shall be prepared by cutting four specimens: two 2-1/2 by 5-1/2 inches and two 5-

1/2 inches by 5-1/2 inches. The pouch shall be fabricated by sealing as shown on figure 1. The

butt seals projecting at 1/2-inch seams perpendicular to the faces shall be made prior to sealing

the bottom. The butt seams shall be folded flat at the point of juncture with the bottom seams

before the bottom seals are made.

FIGURE 1. Pouch for seam fabrication test.

4.6.2.2 Procedure. A water solution, containing dye and a 1 percent sodium

dioctylsulfosuccinate) or equivalent as approved by the qualifying activity, shall be made to

produce a distinct color. The solution shall be poured into each sealed pouch to a level of two

inches above the top of the bottom seam. The pouch shall then be suspended vertically. After a

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business