MIL-PRF-22191F

4.6 Verification of performance requirements.

4.6.1 MIL-STD-3010 test methods. Unless otherwise specified, the tests in table VI shall

be conducted in accordance with the identified methods of MIL-STD-3010.

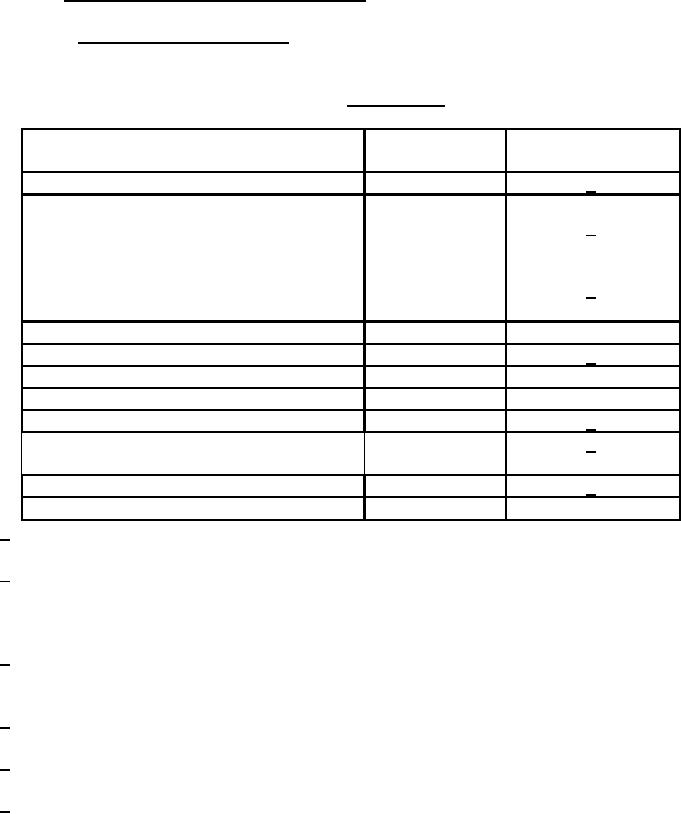

TABLE VI. Test methods.

MIL-STD-3010

Special Requirement

Tests

Test Method No.

or Exception Note

Seam strength

2024

1/

Water vapor transmission rate (type I only)

3030

2/

After room temperature flexing

2017

As received

After Aging

3/

After low temperature flexing (type I only)

As received

Thickness

1003

Puncture resistance

2065

4/

Blocking resistance

3003

Resistance to curl

2015

Contact corrosivity

3005

5/

Oil resistance (delamination) (multi-ply

3015

6/

materials only)

Water resistance of marking

3027

7/

Transparency

4034

---

1/ Any evidence of ply delamination in the heat-sealed area shall be cause for rejection. The

evaluation shall be limited to the heat-sealed area.

2/ Full stroke shall be used for testing all type I materials.

3/ Conduct tests as specified in MIL-STD-3010, Method 2017 except that only `as received'

specimens shall be tested. Prior to flexing, test specimens shall be conditioned for at least 30

minutes at -20 + 2 °F and the flexing operation shall be conducted at -20 + 2 °F.

4/ Test shall be run on 5 specimens with the heat sealable face in contact with the probe and 5

specimens with the non-heat-sealable face contacting the probe. The average value of each set

of specimens shall meet the requirement specified in table I.

5/ If corrosion is evident in the blank area, the test shall be repeated with a new test panel.

Corrosion in the intermediate area shall not invalidate the test nor be cause for rejection.

6/ Oil conforming to ASTM oil IRM-903, as specified in ASTM-D471, and a di-2-ethylhexyl

sebacate synthetic oil shall both be used.

7/ Three specimens shall be tested, each one containing a complete set of markings.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business