MIL-PRF-22019E

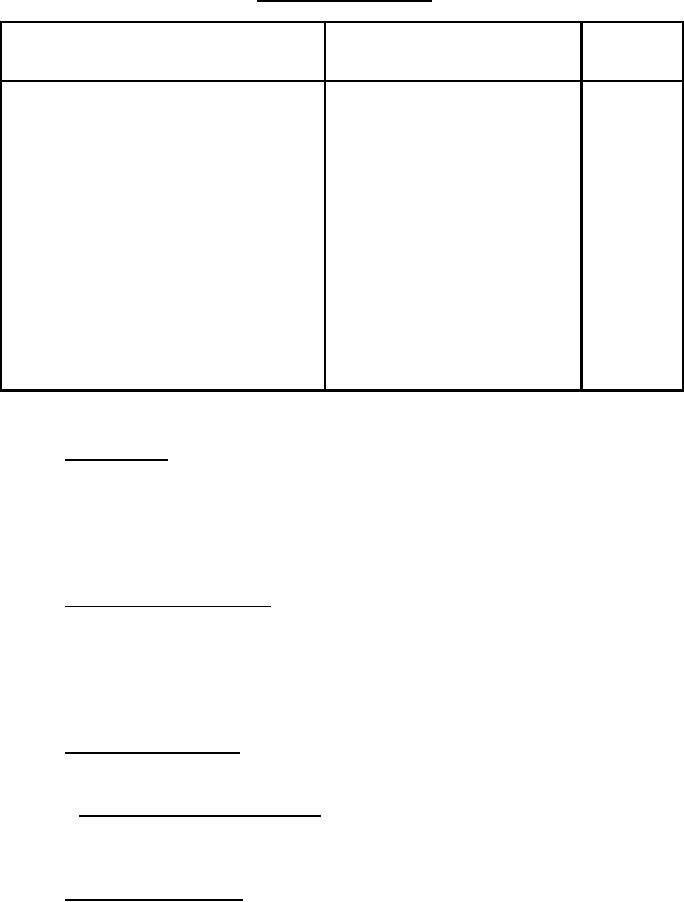

TABLE I. Performance requirements Continued.

Type I and Type II

Test

Requirements

Paragraph

Characteristics

Reference

One year storage stability:

4.6.7

1. Seam strength

a. As received material sealed & tested at

Type I:

25 % (max)

Type II:

50 % (max)

room temperature (seal separation)

b. Sealed after aging at 160 °F for 12 days

Type I:

25 % (max)

Type II:

50 % (max)

and tested at room temperature (seal

separation)

No more than a total of 3 corrosion

2. Vapor inhibitor ability (VIA)

spots on 3 plugs. No corrosion spot

greater than 300 microns in

diameter.

3. Transparency

Lettering shall be legible

a. As received

b. After aging 12 days at 160 °F.

Lettering shall be legible

3.8 Workmanship. Type I barrier material shall have no loose surface deposits. Type II

barrier material shall have no voids in the cohesive sealant (see 4.3.2.2). The barrier material

shall be clean and free from holes, tears, cuts, sharp creases, wrinkles, or other imperfections.

The barrier material shall be cut and trimmed of any selvage (see 4.3.2.1).

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are

classified as follows:

a. Qualification inspection (see 4.2).

b. Conformance inspection (see 4.3).

4.2 Qualification inspection. The qualification inspection shall consist of all tests and

examinations of this specification.

4.2.1 Health/hazard assessment (HHA). The barrier material shall be evaluated by the

Navy Enviromental Health Center (NAVENVIRHLTHCEN), using the administrative HHA (see

6.4.3).

4.3 Conformance inspection. Conformance inspections consist of the required tests listed

in table II and the examinations listed in tables III through V for each production run.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business