MIL-PRF-22019E

1-inch and shall be effected using either of the procedures given below:

a. Use a sealer having two sets of rubber coated pullwheels and opposing jaws, using 40 psi

as the upper sealing conditions;

b. Cut two sheets of Type II barrier material of the appropriate size. Cut a sheet of copier

paper to use as interleaving. Place the first sheet of material, adhesive side up, on a hard, smooth

horizontal surface. Place the interleaving sheet on top of the material to mask areas that are not

to be sealed. Place the second sheet of material, adhesive side down, so that its edges are

superimposed on the first. Roll the unmasked areas using a 2-inch wide, 1 ½-inch diameter hard

rubber roller applying no more than 40 psi pressure normal to the horizontal surface. Roll each

area forward and backward no more than 3 times.

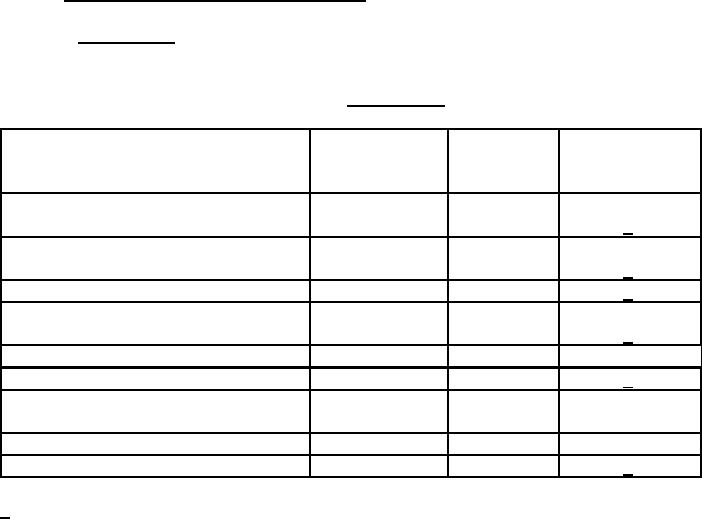

4.6 Verification of performance requirements.

4.6.1 Test methods. Unless otherwise specified, the tests in table VI shall be conducted in

accordance with the identified methods.

TABLE VI. Test methods.

MIL-STD-3010

ASTM

Special

Tests

Test

Test

Requirement or

Method No.

Method No.

Exception Note

Vapor inhibitor ability (VIA)

4031

--

1/

procedure B

Vapor inhibitor ability (after

4031

--

1/

exhaustion)

procedure B

Puncture resistance

2065

--

2/

Blocking resistance

3003

--

3/

procedure A

Contact corrosivity

3005

--

Transparency

4034

--

4/

Water resistance of marking

3027

--

Tearing strength

--

D689

Delamination (oil resistance)

3015

--

5/

1/ The following apply to the VIA and VIA after exhaustion tests:

a. The apparatus used for these procedures shall be cleaned in a solution of hot water and

detergent, followed by thorough rinsing in hot tap water.

b. Four specimens shall be tested.

c. After immersion cleaning in methanol, each specimen shall be allowed to dry for 30

seconds in a draft free area, with the test surface in a vertical position.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business