MIL-PRF-22019E

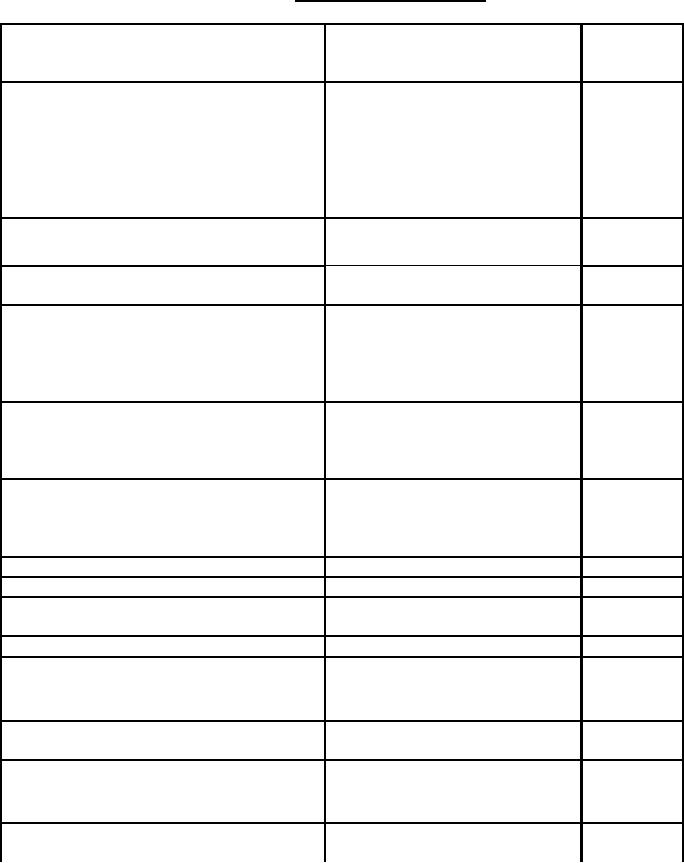

TABLE I. Performance requirements.

Type I and Type II

Test

Requirements

Paragraph

Characteristics

Reference

Seam Strength

Type I: 25 % (max)

4.6.2

1. As received material sealed and tested at

Type II: 50 % (max)

room temperature (seal separation)

2. Sealed after aging at 160 °F for 12 days

Type I: 25 % (max)

Type II: 50 % (max)

and tested at room temperature (seal

separation)

Seam and material water resistance

Seams and barrier shall have no

4.6.3

leakage

Puncture resistance

Type I - 10 lb (min)

4.6.1

Type II - 6 lb (min)

4.6.4

Compatibility with copper

No pitting, etching, dark tarnish

(classification 3), or corrosion

(classification 4) of vapor exposed

surface. Discount attacks within

1

/16-inch of specimen.

Vapor inhibitor ability (VIA)

No more than a total of 3 corrosion

4.6.1

spots on 3 plugs. No corrosion spot

greater than 300 microns in

diameter.

Vapor inhibitor ability (VIA) after exhaustion

No more than a total of 3 corrosion

4.6.1

spots on 3 plugs. No corrosion spot

greater than 300 microns in

diameter.

Contact Corrosivity

No corrosion, etching, or pitting

4.6.1

Low temperature flexibility

No delamination, cracks, or tears

4.6.6

Blocking resistance

No blocking, delamination, or

4.6.1

rupture

Tearing strength (Elmendorf)

50 grams (min)

4.6.1

Transparency

4.6.1

a. As received

Lettering shall be legible

b. After aging 12 days at 160 °F

Lettering shall be legible

Delamination (oil resistance)

No swelling, delamination,

4.6.1

embrittlement,or seal leakage

Long term protection

No corrosion of steel panels.

4.6.5

Barrier material shall comply with

transparency requirement

Water resistance of marking

Markings shall be clear and legible

4.6.1

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business