MIL-PRF-81705E

individual roll shall be not less than 195 yards. The roll material shall be uniformly wound on

nonreturnable cores. The inside diameter of the core shall be not less than 3 inches, with a

tolerance of plus inch. The length of the core shall be equal to the width of the roll material,

with a tolerance of plus inch. The core shall be rigid to prevent distortion of the roll during

use and shipment conditions. Each roll shall be restrained to prevent unwinding (see 4.3).

3.4.2 Sheets. When flat cut sheets are specified, the length and width shall be as specified

by the acquiring activity (see 6.2). If the length and width tolerances for cut sheets are not

specified, the tolerance for each shall be plus ¼ inch or minus inch (see 4.3). Flat cut sheets

shall be evenly stacked (see 4.3).

3.5 Sealing. The barrier material shall exhibit no delamination of the sealed area when

sealed according to the manufacturer's recommended conditions (see 4.5). The barrier material

identification of material markings shall include the sealing conditions (see 3.6). Each roll or

package (flat cuts) of barrier material shall include a tag secured to the core of rolls, or sheet

inserted in the package of sheets with the sealing instructions for impulse seals and for heat-

sealing on rotary, band and jaw type sealing equipment. The tag or sheet shall be visible upon

opening the unit package (see 4.3).

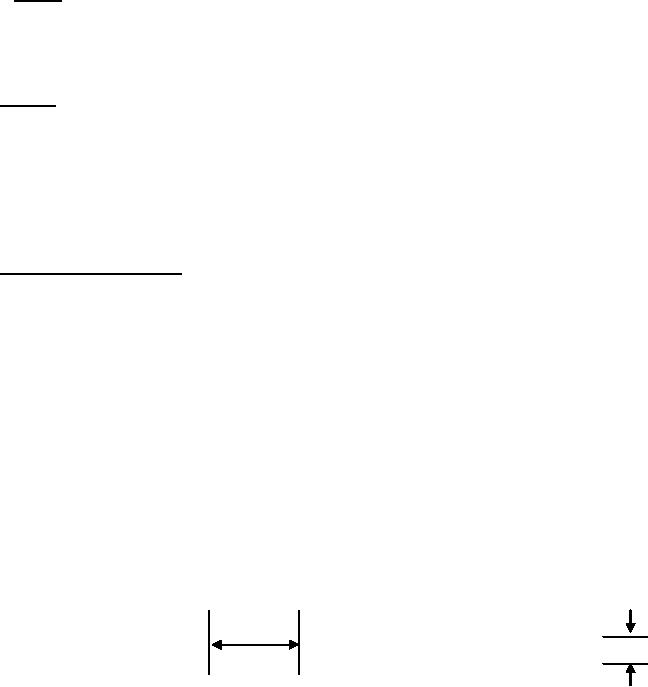

3.6 Identification of material. The barrier material shall have two groups of markings in

block form and in machine direction. Group A marking shall state the specification number,

type, class, manufacturer's name, manufacturer's designation, month and year of manufacture, lot

number and heat sealing conditions (temperature, pressure and dwell time). The letters and

figures shall be clear, legible, and shall be not less than inch high. Group B markings shall

identify the protective qualities of the materials as follows: For type I EMI/STATIC SHIELD

and for type III STATIC SHIELD. These letters shall be not less than ½ inch high. The two

groups of markings on all three types of material shall be either printed using a water-resistant

ink or embossed and shall be visible if the material is fabricated into a bag or pouch. The two

groups of markings shall be printed or embossed sequentially, complete, and continuous

lengthwise with a space of one inch between groups. A complete group of markings shall appear

once in each six inches of width of the roll and flat cut. An example of the identification is as

follows (see 4.3):

NOTE: Both Date and Lot Number shall change for each production run.

MIL-PRF-81705E TYPE I CLASS 1

1"

MFR NAME MFR DESIGNATION

EMI/STATIC SHIELD

½" MIN

DATE

LOT NUMBER

SEALING CONDITIONS:

XXX °F, YY PSI, Z SEC

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business