MIL-PRF-81705E

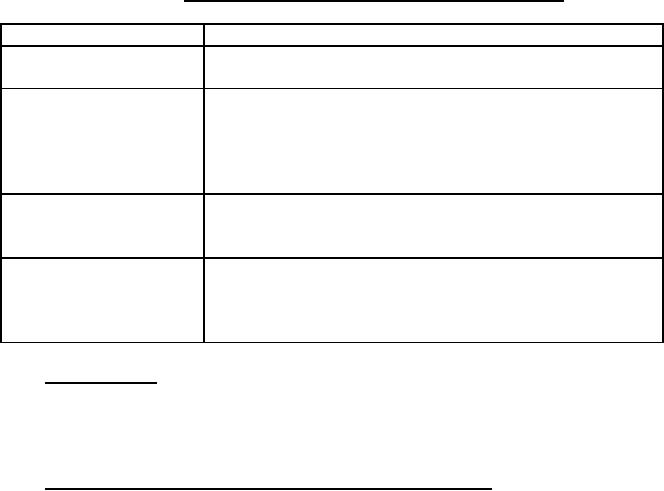

TABLE V. Examination of the end item for dimensional defects.

EXAMINATION

DEFECT

Sheets

Length or width varies by more than plus ¼ inch or minus

inch from dimensions specified.

Rolls:

Width

Varies by more than plus or minus ¼ inch from width

specified.

Length

Length of any individual roll is less than 195 yards, or the

average length of roll material is less than 200 yards.

Core

Length of core is less than width of roll material or greater

by more than plus inch.

Inside diameter less than 3 inches or greater than 3 inches.

Identification markings

Lettering is less than inch in height for Group A markings.

Lettering is less than ½ inch in height for Group B markings.

The complete grouping (A and B) does not appear every 6

inches lengthwise.

4.4 Test conditions. Unless otherwise specified in the detailed test methods herein, the

physical tests contained in this specification shall be made with an atmosphere having a relative

humidity of 50 ± 5 percent and a temperature ranging from 70 to 76 °F. Barrier material shall be

considered in equilibrium after exposure to the above conditions for a minimum of 24 hours.

4.5 Sealing instructions for qualification and conformance testing.

a. All seals for test purposes shall be not less than ½ inch wide and shall be effected on a

jaw-type heat-sealer or equivalent as approved by the qualifying activity utilizing the

sealing conditions recommended by the manufacturer. These conditions shall be limited

as follows (see 6.3):

(1) Maximum temperature

=

525 °F

(2) Maximum dwell time

=

3 seconds

(3) Maximum pressure

=

60 psig

b. Impulse seals for test purposes shall be a minimum of ¼-inch wide and shall be effected

on impulse sealers, or equivalent as approved by the qualifying activity. The upper

sealing limits on the sealer shall effect a seal and not cause thinning at the inside edges of

the seal.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business