MIL-PRF-3420H

4.5 Verification of performance requirements.

4.5.1 Test methods. Unless otherwise specified, the tests in table VI shall be conducted in

accordance with the identified methods.

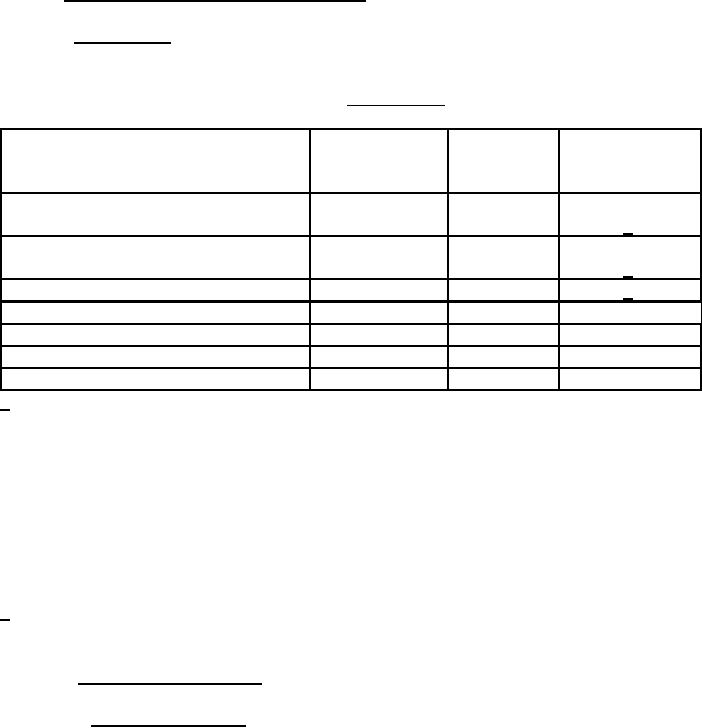

TABLE VI. Test methods.

ASTM

Special

MIL-STD-3010

Test

Tests

Requirement or

Test

Method No.

Method No.

Exception Note

Vapor inhibitor ability

4031

--

procedure B

1/

Vapor inhibitor ability (after

4031

--

1/

procedure B

exhaustion)

Blocking resistance

3003

--

2/

Contact corrosivity

3005

--

Bursting strength

D774

Water resistance of marking

3027

--

Tearing strength

--

D689

1/ The following apply to the VIA and VIA after exhaustion tests:

a. The apparatus used for these procedures shall be cleaned in a solution of hot water and

detergent, followed by thorough rinsing in hot tap water.

b. Four specimens shall be tested.

c. After immersion cleaning in methanol, each specimen be allowed to dry for 30 seconds in

a draft free area, with the test surface in a vertical position.

d. Immediately after insertion into the VIA test apparatus, each specimen shall be blown free

of dust using a short burst from a self pressurized can of 1,1,1,2 tetrafluoroethane.

e. After eliminating the plug with the most corrosion spots, the remaining three plugs shall

meet the requirement in table I.

2/ (Style C materials shall be tested in a face-to-back configuration only.) Samples shall be

tested at both room temperature and 160 °F.

4.5.2 Long term protection test.

4.5.2.1 Preparation of panels. Four 2 by 4 by 1/8 inch, cold rolled SAE1010 steel panels,

with rounded edges shall be finished and cleaned as specified in the contact corrosivity test (see

4.5.1). Two 1/8 inch diameter holes shall be drilled at opposite corners of a 4 inch side.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business