MIL-PRF-3420H

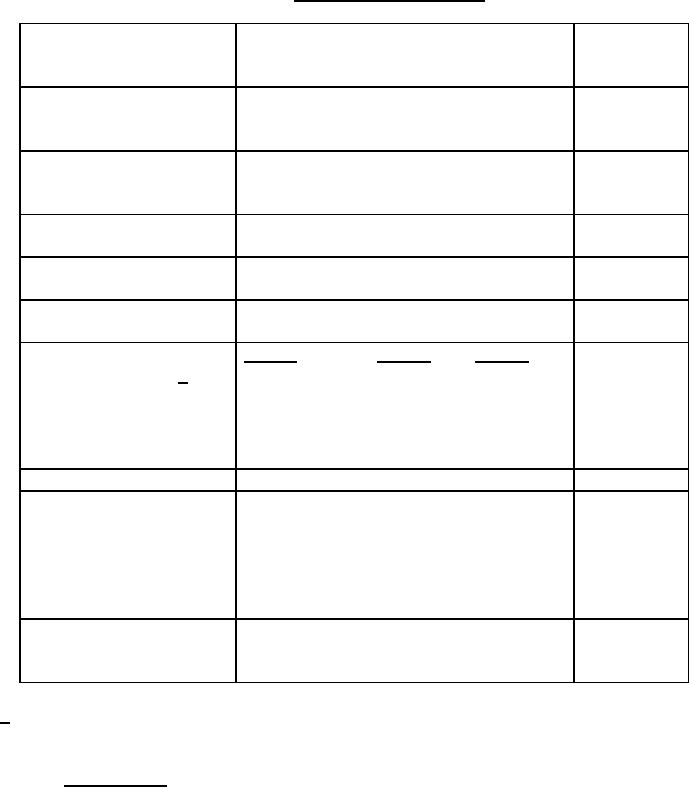

TABLE I. Performance requirements.

Characteristics

Requirements

Test

Paragraph

Reference

Vapor inhibitor ability

No more than a total of 3 corrosion spots on

4.5.1

(VIA)

3 plugs. No corrosion spot greater than 300

microns in diameter.

4.5.1

No more than a total of 3 corrosion spots on

Vapor inhibitor ability

3 plugs. No corrosion spot greater than 300

after

exhaustion

microns in diameter.

Contact corrosivity

No corrosion, etching or pitting of contact

4.5.1

area of panel.

Blocking resistance

No blocking, delamination, tearing or

4.5.1

flaking when the sheets are separated.

Water resistance of

Markings shall be clear and legible.

4.5.1

markings

Strength:

Class 1

Class 2

Class 3

Bursting (psi min) 1/

60

40

20

4.5.1

Tearing, machine and

110

40

12

4.5.1

cross directions (gms min)

Long term protection

No corrosion of steel panels.

4.5.2

No pitting, etching, dark tarnish

Compatibility with copper

4.5.3

(classification 3), or corrosion

(classification 4) of the vapor exposed

surface. Discount attacks within 1/16 inch

of specimen.

4.5.4

Compatibility with

No delamination, swelling, embrittlement,

MIL-PRF-131 barrier

dissolution, effect on the sealability or

material

deterioration of barrier material.

1/

On crepe material, bursting strength value shall be obtained with specimen stretched. Crepe

requirement shall be 50 percent of flat.

3.7 Workmanship. The appearance of finished wrapping materials that are coated or

impregnated shall not contain any voids in the coating or substrates (see 4.3.2.2). The material

shall be clean and free from holes, tears, cuts, sharp creases, wrinkles, or other imperfections.

The treated carrier shall be cut and trimmed of any selvage (see 4.3.2.1).

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business