MIL-PRF-3420H

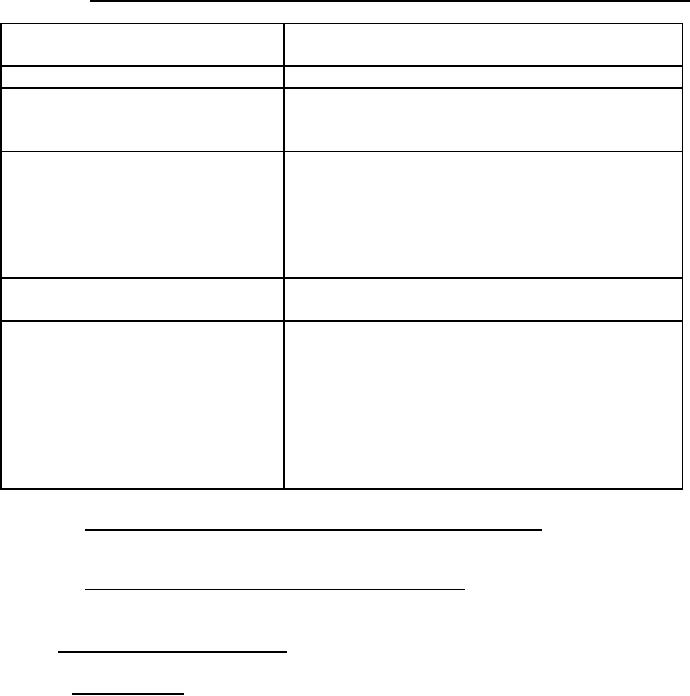

TABLE III. Examination of end item for defects in appearance, construction, and workmanship.

EXAMINATION

DEFECT

(Check both sides of treated carrier.)

Form of material

Not rolled or flat cut, as specified.

Appearance

Surfaces not clean; presence of any foreign matter,

dirt, sand, grit or oil spots. (NOTE: Defects do not

apply to outer convolution of roll.)

Workmanship

Delamination.

Embrittlement.

Any hole (excluding optical pinholes), tear, cut,

chafed spot or scuff mark. (Note: Defects do not

apply to outer convolution of roll.)

Edges not clean cut; ragged, crushed or uneven.

Construction

Not uniform.

Any layer or section missing.

Identification of material (marking)

Markings not made using water resistant ink.

Missing, incorrect, or illegible.

Not on backing surface where required.

Complete marking not repeated as specified in 3.5.

For roll material the lines of print not perpendicular

to the longer sides of material.

Tags or sheets, when applicable, not properly

located.

4.3.2.2 Examination of the end item for defects in general construction. The sample unit

for this examination shall be one roll or one package of sheets, as applicable.

4.3.2.3 Examination of the end item for dimensional defects. The sample unit for this

examination shall be one roll or one package of sheets, as applicable.

4.4 Test conditions and preparation.

4.4.1 Test conditions. Unless otherwise specified in the detailed test method herein, the

physical tests contained in this specification shall be made with an atmosphere having a relative

humidity of 50 ± 5 percent and a temperature ranging from 70 to 76°F (21 to 25°C). Material

shall be considered in equilibrium after exposure to the above conditions for a minimum of 24

hours.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business