MIL-DTL-17667E

4.5 Verification of performance requirements.

4.5.1 Standard test methods. The tests listed in table III shall be conducted in accordance

with the specified test methods.

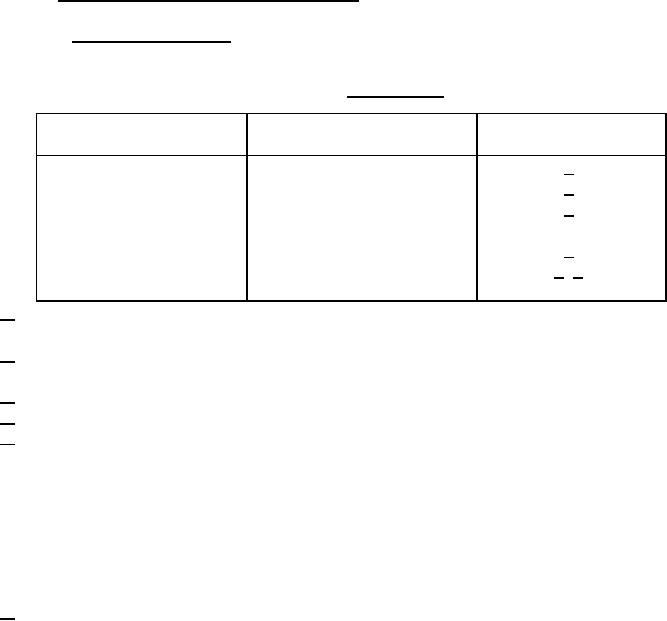

TABLE III. Test methods.

Special requirement or

Tests

Test method

exception note

Basis Weight

TAPPI T410

1/

Bursting Strength

TAPPI T403

2/

Tearing Resistance

TAPPI T414

3/

Tensile Breaking Strength

TAPPI T494

Elongation (Type II only)

TAPPI T494

4/

Contact Corrosivity

MIL-STD-3010, Method

5/ 6/

3005

1/

Sample size shall be five sheets, each measuring 24 by 36 inches. Basis weight shall be

verified by extrapolation to a ream quantity.

2/

Sample size shall be six specimens. Test shall be conducted three times with material face-

up and three times face-down. All samples must meet the requirement.

3/

Sample size shall be ten specimens, five from each principal direction of the material.

4/

Test in creped direction only.

5/

The following test surface shall be used for testing and shall be exposed for 72 hours:

· Brass per ASTM-B121

· Cadmium per A-A-51126

· Copper per ASTM-B133

· Zinc per MIL-A-18001

· Aluminum per ASTM-B209

· Magnesium per SAE-AMS4375

· Nickel per ASTM-A265

6/

Light brown, purplish, pinkish, bluish or "peacocking" staining and other discoloration of the

copper panels normally associated with oxidation of copper shall not be considered cause for

final rejection of the material. In case of apparent corosion on copper panels, a sodium

azide-iodine test shall be conducted to check for the presence of sulfur bearing compounds

on the panels. A drop of freshly prepared sodium azide-iodine solution, prepared by

dissolving 1.3 g of iodine and 4 g of potassium iodide in 100 ml of water to which is added 3

g of sodium azide to the mixture, shall be placed in the test panels. An immediate and

profuse deverlopment of gas, in the form of tiny bubbles rising through the liquid, indicates a

positive test for sulfides. A magnifying glass or microscope is necessary for observing the

bubble formation. A slow steady evolution of scattered bubbles is not a positive test for

sulfides.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business