MIL-DTL-82646B (OS)

4.3.1.1 Lot. A lot shall consist of 50,000 yd2 (41,800 m2)of material or less, manufactured by the same

process, from the same components, by one manufacturer, at one plant and offered for delivery at one

time.

4.3.1.2 Sampling for examination Samples for examination shall be selected in accordance with

inspection level II, single sampling, normal inspection of ASQ Z1.4. Sufficient material shall be selected

at random so that the required sample yardage is obtained.

4.3.1.3 Sampling for tests. For the purpose of maintaining continuous inspections, test samples shall be

taken from material packed for shipment. The lot (4.3.1.1) shall be divided into five equal segments.

Five sample rolls shall be drawn from the lot for test, one from each of the five equal segments. Each test

sample consisting of 6.0 yd2 (5.0 m2) shall be assigned a number from one to five in order of manufacture.

4.4 Periodic production inspection. When specified in the contract or order (see 6.2). periodic production

samples shall be forwarded to an activity specified by the procuring activity (see 6.2) for periodic

production inspection.

4.4.1 Periodic production samples. Periodic production samples shall be selected from plastic film that

has passed the quality conformance inspection of 4.3. The sampling plan shall be as specified by the

procuring activity (see 6.2).

4.5 Examinations. Sample material shall be visually inspected to verify conformance with this

specification. Defect classification shall be in accordance with Table II.

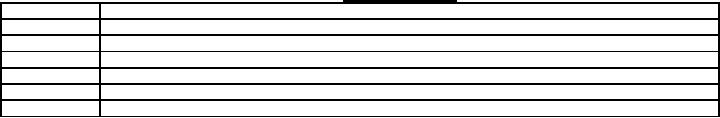

TABLE II. Types of defects.

Examination

Defects

Form

Rolled or flat cut not as specified, lay flat dimensions or film thickness not as specified

Cleanness

Not clean

Workmanship

Embrittlement or any hole, tear, cuts, chafed spot, or other defect that would impair usefulness of film

Construction

Not uniform; pinholes, cracks, blisters, scratches, mottling, folds, foreign matters, gels, or fish eyes

Color

Not uniform

Identification

Marking not as specified. Identification sheet missing.

4.5.1 Examination for roll or package defects. The lot size for this examination shall be expressed in units

or packages of sheets.

4.5.2 Examination for appearance and workmanship. The lot size for this examination shall be expressed

in units of square yards of film. Defects shall be scored only once for each occurrence within a square

yard.

4.6 Tests. Film samples shall be subjected to the following tests. Failure of any sample to pass any test

shall be cause for rejection of the lot.

4.6.1 Test condition. Prior to testing, film samples shall be conditioned for 24 hours minimum in a

moving atmosphere having a relative humidity of 50 ± 5 percent and n temperature of 21º to 24.5 ºC (70º

to 76 º'F).

4.6.2 Chemical compatibility. The film shall be tested for compatibility with the chemicals listed in 3.4.1.

The test procedure shall be in accordance with Method 7081 of FED-STD-206, with the following

exceptions:

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business