MIL-DTL-82646B (OS)

3.6 Workmanship. The film shall be uniformly constructed and free from pinholes, tears, cuts, sharp

creases, or other imperfections which might impair the usefulness of the film. The color is optional but it

must be uniform and not mottled.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as follows:

a. First article inspection (see 4.2)

b. Quality conformance inspection (see 4.3)

c. Periodic production inspection (see 4.4).

4.2 First article.

4.2.1 First article sample. Unless otherwise specified, a first article sample shall consist of a roll of film

50 yards (yd) (45.7 m) long and 36 in. (91.4 cm) wide upon which first article testing is desired. The

sample shall be tested by the manufacturer or forwarded to a testing facility as directed by the procuring

activity (see 6.2). If the sample is to be forwarded to a testing facility, the sample shall be plainly

identified by a securely attached durable tag marked with the following: "Plastic Film, Conductive, Heat-

Sealable, Flexible, For Ordnance Use. Sample for First Article Test"; Manufacturer's name and address;

manufacturer's designation; date of manufacture: and "Submitted by (name) (date) for first article test in

accordance with the requirements of MIL-DTL-82646 under authorization (reference authorizing letter)".

4.2.2 First article testing. First article testing shall be as specified in Table I. Failure to meet any

requirement shall be cause for rejection of the first article sample. The contractor shall prepare a report

giving the result obtained for all inspections and tests performed or a certified statement that the first

article sample meets all the first article requirements of this specification.

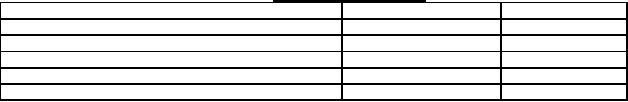

TABLE I. First article inspection.

Inspection

Requirement paragraph

Method paragraph

Examination

3.2, 3.3, 3.5, 3.6

4.5

Chemical compatibility

3.4.1

4.6.2

Solvent compatibility

3.4.2

4.6.3

Electrical resistivity

3.4.4

4.6.5

Film tensile strength, breaking strength and elongation

3.4.5

4.6.6

4.2 3 First article retest. Material rejected by the Government testing agency may be retested for first

article acceptance (see 6.3.1).

4.2.4 Retention of first article approval. Retention of first article approval for products shall be maintained

by periodic verification to determine compliance of the first article product with the requirements of this

specification. Unless otherwise specified by the procuring activity, periodic verification shall be by

certification and such certification shall be at intervals of not more than 2 years.

4.3 Quality conformance inspection. The material shall be subjected to all the following inspections and

tests for acceptance. When specified in the contract (see 6.2). the contractor shall prepare a report giving

the results obtained for all inspections and tests performed and a certified statement that the lot meets all

the requirements of this specification (see 6.2.2).

4.3.1 Sampling for quality conformance inspection.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business