MIL-PRF-131K

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are

classified as follows:

a. Qualification inspection (see 4.2).

b. Conformance inspection (see 4.3).

4.2 Qualification inspection. The qualification inspection shall consist of all tests and

examinations of this specification.

4.3 Conformance inspection. Conformance inspections shall consist of the required tests

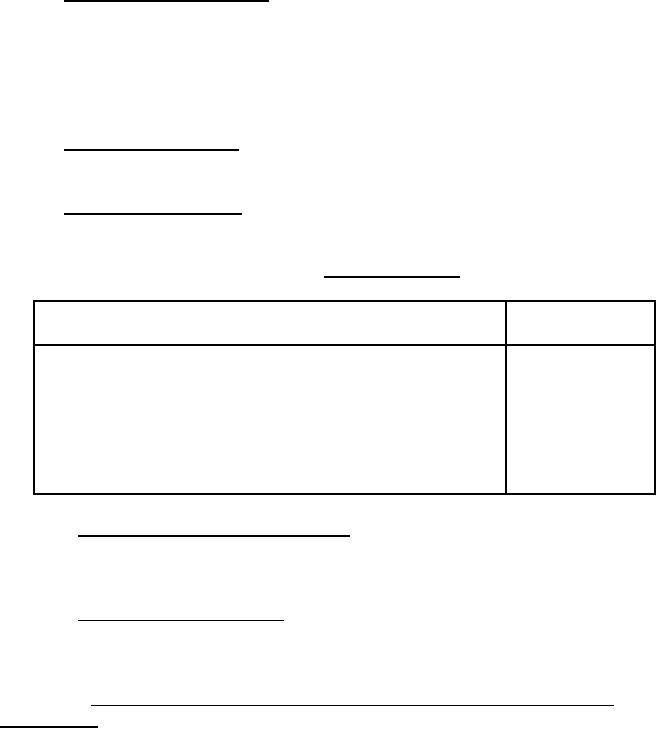

listed in table II and the examinations listed in tables III through V.

TABLE II. Conformance tests.

Characteristics

Paragraph

Reference

4.6.1

Seam strength (as received only)

4.6.2

Seam fabrication (class 1 & 3 only)

4.6.1

Water vapor transmission rate (as received only)

4.6.5

Breaking strength (as received only)

4.6.1

Puncture resistance

4.6.1

Resistance to curl

4.6.6

Tear strength (class 3 only)

4.3.1 Sampling for conformance inspection. Unless otherwise specified in the contract or

order, sampling for inspection shall be performed in accordance with the provisions set forth in

ASQ-Z1.4.

4.3.2 Examination of the end item. For the purpose of determining the sample size in

accordance with ASQ-Z1.4, the lot size shall be expressed in units of rolls or packages of sheets,

as applicable, for examinations under 4.3.2.1 through 4.3.2.3.

4.3.2.1 Examination of the end item for defects in appearance, construction, and

workmanship. For examination of defects within rolls, the sample unit of product shall be two

yards, the full width of the roll. For examination of sheets, the sample unit shall be two sheets

randomly selected from a package. No more than five sample units, randomly selected, shall be

drawn from any one roll or package of sheets, as applicable. Both sides of the material shall be

examined.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business